The Future of Tilt-Up Construction

Tilt-up construction has long been valued for its speed, cost-efficiency, and strength. However, traditional punch or framed windows installed after panels are tilted often introduce added costs, labor inefficiencies, water leaks, ongoing caulking maintenance, alignment issues, and inconsistent aesthetics.

Integrated Window Systems® (IWS) has changed that with the only cast-in-place window system designed specifically for tilt-up construction. Engineered for performance and built to simplify the jobsite, the IWS system continues to draw interest from architects, general contractors, design-build teams, and concrete professionals seeking smarter, faster, and more reliable solutions.

Cast-In-Place System with IWS®

Our approach integrates clerestory punch windows directly into the tilt panel during casting. Frames are set into the forms before the concrete is poured, allowing them to be embedded, aligned, and securely positioned with precision from the start.

Using a simple three-step process—Set → Place → Tilt—IWS eliminates many of the costly and time-consuming steps of traditional installations. Because the windows are cast in place, there’s no need for exterior caulking or finishing work at the frame-to-concrete interface. This eliminates common failure points and dramatically reduces long-term maintenance.

Reliable Installation System with Reduced Risk

IWS simplifies the process by embedding windows directly into the tilt panels, eliminating multiple steps and trades. Key benefits include:

- Streamlined Workflow – By casting windows into panels, IWS eliminates blocking out openings and reinstalling framework, saving substantial time and labor.

- Immediate Dry-In – Panels are dried-in once tilted, protecting interiors and minimizing weather-related delays.

- Low-Maintenance Finish – No exterior caulking required, resulting in a cleaner look and reduced long-term maintenance.

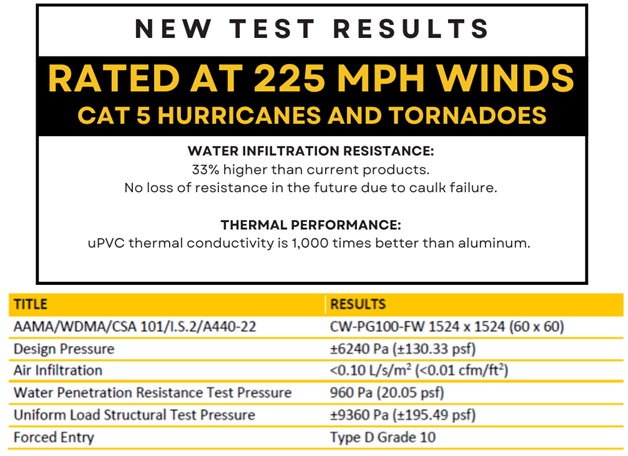

- Durability & Performance – Rated for winds up to 225 mph, 130 psf design pressure, and 1,000 times the thermal efficiency of aluminum windows—all without the risk of corrosion.

The impact: General contractors reduce scheduling risks, cut down on trade conflicts, and deliver a higher-quality finished building that enhances their reputation with owners and architects alike

High Performance Technology

Each unit is rigorously tested to meet high performance standards for design pressure, wind load, and durability, and offers flexibility with full glass options, multiple colors, and compatibility with standard wall widths.

In the field, IWS’s system has proven to streamline projects and improve outcomes for the entire build team, delivering faster coordination, lower risk, and more consistent results.

Take the Next Step in Advancing Your Tilt-Up Projects

As the tilt-up industry continues to evolve toward faster, safer, more durable, and more aesthetically refined buildings, cast-in-place window systems represent a true leap forward. For every stakeholder—contractors, architects, owners, and glaziers—the benefits are clear: lower cost, shorter schedules, higher quality, less maintenance, and better peace of mind.

If you’re ready to explore how IWS’s Cast-In-Place Window System can elevate your next project by reducing waste, streamlining coordination, and ensuring long-term performance, contact our team today for specifications, pricing, and a project consultation.

Contact:

Integrated Window Systems

Phone: 1-800-613-8148

Email: info@iwstilt.com

Let us partner with you to build smarter, stronger, and better.